When I found this Amiga 1200, I felt pity for it. The case and keyboard was very yellowed, but what was even worse was the screwed up attempt to fit a Gotek drive into the case. The previous owner obviously tried to open the floppy disk area with some kind of cutter pincers, essentially ruining the case.

My initial plan was to whiten the case and keyboard, clean the botched cut at the floppy drive with a rotary tool, and nicely close it again with a 3D-printed part. But then I got a better idea. 😁

The Mainboard

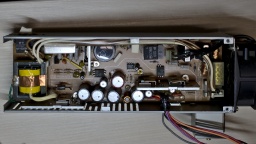

Let's have a look inside first. There is a Rev 1D.4 board in good optical condition. I replaced the electrolytic capacitors, and upgraded the ROMs to AmigaOS 3.2.1.

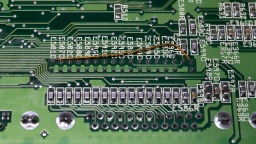

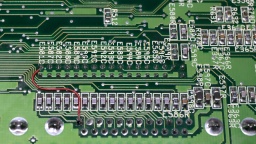

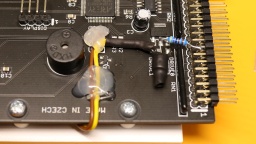

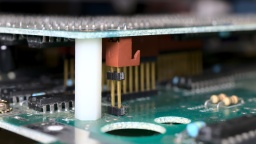

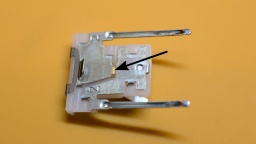

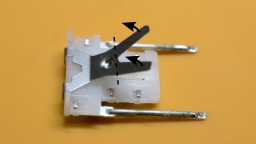

On the bottom of the PCB, I found a copper wire for a so-called "floppy fix". When Escom was producing the final batch of Amiga 1200 systems, Amiga floppy drives were not available any more, and Escom had to find a way to use regular PC floppy drives instead. However, many games and demos with own trackloaders fail to load on machines with this modification.

The original floppy drive of this machine was not existing anymore, and Gotek drives can perfectly emulate Amiga floppy drives, so I decided to undo the floppy fix by removing the botch wire. To restore the original RDY signal, I instead put a wire from pin 34 of the internal floppy connector to pin 1 of the external connector.

Since I was working on the bottom side of the PCB, I should also remove E123C and E125C, to enhance the stability of accelerator boards. However, on this machine these capacitors were not populated, so there was nothing to do.

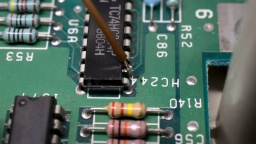

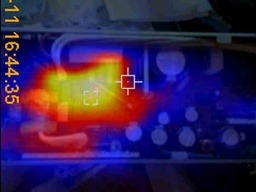

It was finally time for a first thorough test run. Everything went fine, but then I noticed that the right mouse button was not working on both ports. I wrote a separate blog article about the cause and the fix, but to make a long story short, all I had to do was to replace four resistors with ferrites.

My work on the board was completed after that, and it passed all tests.

The Extras

As with my other refurbishments, I'm not only cleaning the machine, but I also futureproof it with some extras.

First of all: The yellowed case with the ugly cut. I was sure that even with a skillful repair attempt, the case would never look really beautiful again. Also I always wanted to have a black Amiga, so I decided to rehouse the machine into a brand new, black a1200.net replica case instead.

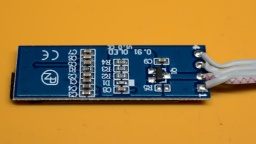

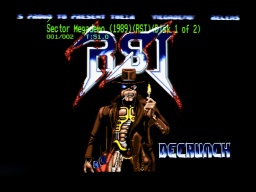

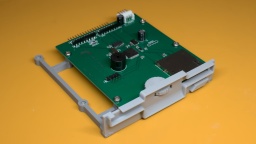

The floppy drive was missing, but instead of the Gotek drive that was there as replacement, I decided to use a Centuriontech GoEX drive. It uses an SD card instead of an USB stick, and comes with a dial encoder, which makes selection of a floppy image much easier. There is also a matching OLED display for it, but for my new Amiga I preferred to use a tiny display that is not that noticeable.

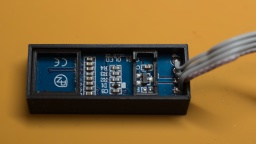

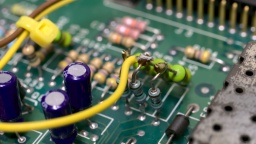

The display itself is one of those 0.91" OLEDs one can find in virtually every maker shop. However it is important to swap pin 1 and 2 when soldering wires to it, as the power pins are swapped on this display type compared to the original GoEX display module.

I then printed an A600 display module case, which luckily also fits on an A1200. I used hot glue to assemble the module, but in retrospect I should have used standard glue instead, since the hot glue softened the PLA of the print. The module is then just clipped into the cooling vents of the Amiga, no need for gluing.

To use this kind of OLED, a file called FF/FF.CFG needs to be created on the SD card, which contains this line:

display-type = oled-128x32

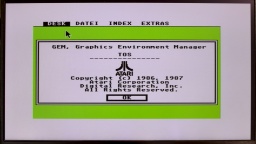

I also added an Indivision AGA MK3 for a pixel-perfect picture on modern TVs via HDMI. While doing so, I found out that the a1200.net replica case seems to have different measures than the original case, so I created a modified trapdoor and holder for this kind of case.

The computer came with a Marpet Developments M1207 RAM expansion in the expansion port. It got a fresh button cell, and now provides the machine with 4MB of additional Fast RAM, a 68882 FPU, and a RTC.

Assembling

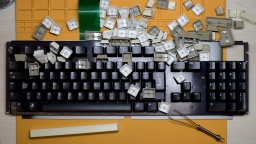

What's missing? The black keycaps that are matching the black case! After many years of waiting they were finally available, and I got a set delivered right in time before Christmas.

The black case does not include badges, but I found a nice black one from Badgeman.

After that, the Amiga was finally ready for the final assembly.

If Commodore had given the choice of the case color back in the 1990's, I would have chosen a black Amiga. And now here it is, an all black Amiga 1200 with a completely new outerior, and modernized interior.