One year or so after I got my Amiga 500, I extended it with a GVP Impact Series II A500-HD+ SCSI host adapter and a 45MB harddisk. It retired together with the Amiga 500, and was stored in the basement for decades. But while the Amiga survived the years in a surprisingly good state, the GVP had suffered from the moisture. The case was yellowed, but also got mold stains, and the metal frame got some flash rust.

All in all, it seemed to be in a bad shape that was difficult to restore. But on the other hand, it would be sad to write off this nice piece of hardware, while all the other Amiga stuff got a general overhaul.

I sent the case to the CBM Museum Wuppertal for cleaning and whitening. It was a bit embarassing to send it in that bad condition, but they said it can be cleaned and will then look as good as new. Let's see if they can do miracles.

Flash Rust

The base frame had a lot of dirt and flash rust from the storage, especially in the areas that are frequently touched. I used some Nigrin car metal polish paste to clean it, but probably every kitchen metal polish would have done the job as well. It was a bit of work, but after that it almost looked as new.

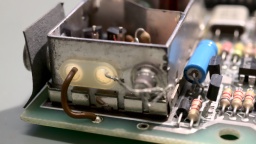

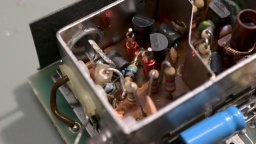

Self-Powering

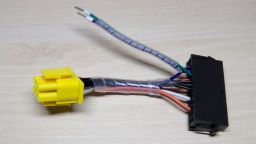

There have been two things that were always annoying me on this controller. One was the tiny fan that was supposed to cool the harddisk, but produced a lot of noise. The other one was that a separate external PSU was needed to power the harddisk.

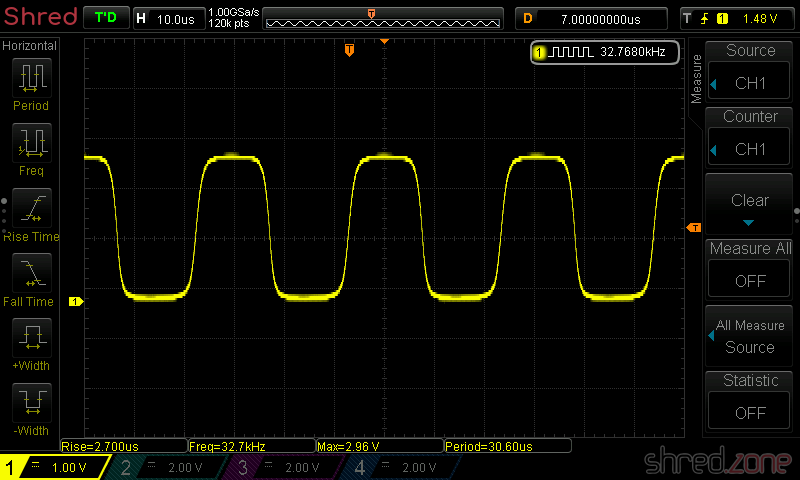

I always wished that the controller would just source itself from the Amiga, but it was clear to me that the mechanical harddisk was drawing too much power for that. The original Fujitsu drive consumed about 10W! With a SCSI2SD adapter, the power consumption is considerably lower, so a self-powering is feasible. The SCSI2SD V5.2 adapter draws only about 10mA, or 0.05W.

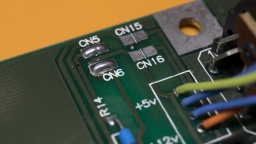

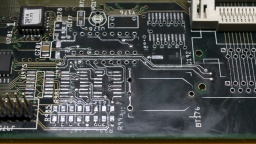

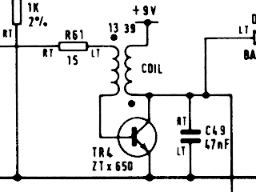

The controller can easily be modified to get its power from the Amiga. There is a blog post by davem2 explaining it. All one needs to do is to bridge the CN5 and CN6 pads with some solder.

Since the SCSI2SD adapter also does not need active cooling, I could finally keep the loud case fan disconnected for good.

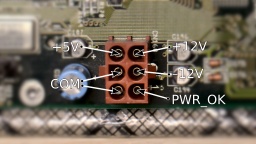

After the modification, make sure never to connect the GVP PSU to the controller again. It would power the Amiga via the card connector, which is very likely to cause damage to your hardware. Also, do not use mechanical harddisks after the modification. If you want to keep using the original PSU instead, you should let a technician check it first.

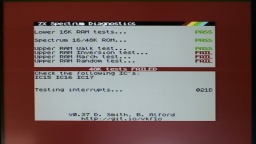

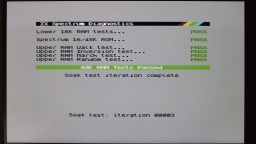

Firmware Upgrade

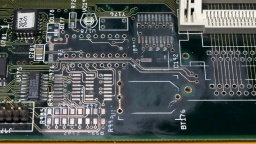

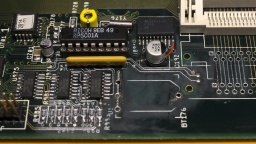

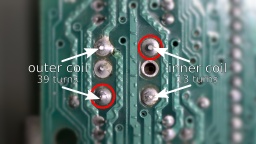

By a lucky chance, I found the latest firmware v4.15 in Ralph Babel's Amiga archive. By another lucky chance, I also found a 27128 EPROM in my spare part box that was once stripped from an old mainboard.

The original firmware would have worked fine as well, but if there is an opportunity for a free update, why not take it?

If you should use a 27256 EPROM instead, make sure to burn the image twice, as only the upper half of the memory will be accessed by the hardware.

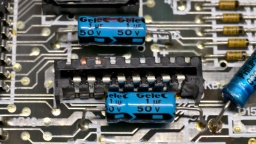

Final Works

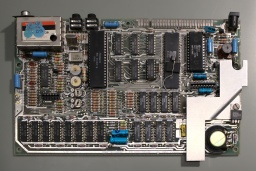

As there are no electrolytic capacitors on this board, there is no need for recapping. I still did a minor modification: I replaced the LEDs with blue (power) and red (disk) ones, as it became a kind of signature color for all my computers.

After that, I gave the board a thorough bath in IPA, and cleaned the edge card connector with a contact cleaner.

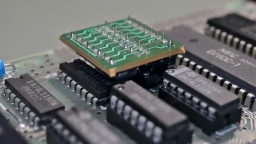

I also found two 1MB/70ns 30-pin SIMM modules for a few Euros on the Bay, so I could double the available Fast RAM to stunning 4MB in total. (Remember to change the jumpers accordingly, as there is no automatic detection.)

Reassembly

Meanwhile the CBM Museum Wuppertal had returned the cleaned and whitened cover. They did an excellent job! The case looks almost as good as new. The mold and dirt stains are gone, and the whitening brought back the original "Amiga beige" color.

As the SCSI2SD adapter is delivered without any kind of mounting frame, I had to 3D-print one myself. Unfortunately it collided with the case fan, so eventually I just removed it completely.

And that's it. The GVP harddisk controller is reunited with its Amiga 500 again. I am sure they have missed each other. 😉

The ugly duckling finally became a beautiful swan again!