The main way to load software into the ZX Spectrum was via audio tapes. There have been floppy drive extensions and Sinclair's proprietary Microdrive solution, but audio tapes were cheap and ubiquitous, and cassette recorders could be found in virtually every household.

The main way to load software into the ZX Spectrum was via audio tapes. There have been floppy drive extensions and Sinclair's proprietary Microdrive solution, but audio tapes were cheap and ubiquitous, and cassette recorders could be found in virtually every household.

The downside was that it was uncomfortable. Tapes are slow. It took several minutes to load a game into the machine. If you had a "collection" of multiple games on one tape, you first had to wind it to the correct position. When I got my first Amiga with floppy drive, I never really looked back to those times when I had to use audio tapes.

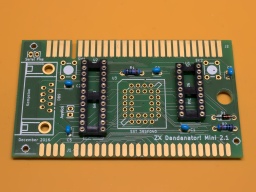

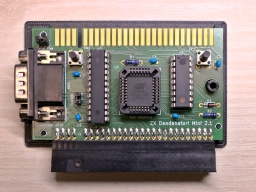

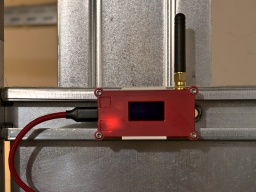

Today I own a couple of ZX Spectrums, but I don't have a tape recorder anymore. To load software into the machine, I usually use my PC's headphone jack and tzxplay. But there is a more elegant way. The ZX Dandanator Mini by Dandare is an extension with 512KB of Flash memory where you can store your most favorite games. A boot menu permits to select one of these games, which is instantly loaded into memory. It also provides a Kempston compatible joystick port.

When I started to build my ZX Dandanator Mini, I found that the documentation of the project left a few questions open. I hope my comprehensive blog article will help others to build their own one.

Parts

Fortunately, the Dandanator's bill of materials is quite short, and all the components are easy to find, maybe except of the edge connector.

Fortunately, the Dandanator's bill of materials is quite short, and all the components are easy to find, maybe except of the edge connector.

- 1x GAL 22V10 (+ DIP20 socket)

- 1x PIC 16F1826-I/P (+ DIP18 socket)

- 1x SST 39SF040 Flash ROM (+ PLCC32 socket)

- 1x 1N4148 (TH)

- 2x 10kΩ resistors (TH)

- 5x 100nF ceramic capacitors (TH)

- 1x D-Sub connector, 9-pin male, right angle, Europe style (e.g. this one)

- 2x pin headers, 2-pin

- 1x jumper

- 2x 6 mm tactile switches (17 mm tall if you use the 3D printed case)

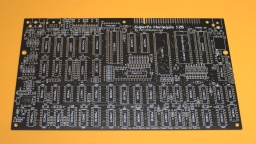

- 1x PCB (Gerber files are here)

- 1x ZX Spectrum edge connector (can be found in retro shops, online marketplaces, or just DIY)

- 1x 3D printed case (optional)

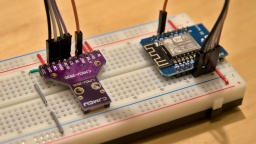

You will need a programmer that is able to flash the PIC, GAL, and Flash ROM (e.g. XGecu TL-866II Plus with PLCC32 adapter). I also recommend a good PLCC chip puller.

Classic GALs are out of production, but can still be found as NOS parts in online marketplaces. A replacement that is still produced is the Atmel ATF22V10C-10PU. If you use that one, you will also need a 3.3kΩ 6-pin bussed resistor array. More about that below.

Assembly

The assembly is straightforward. You start with the flattest components and work your way up to the tallest. There are no SMD components, so even a soldering novice should have no problem.

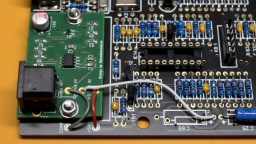

Make sure the sockets are oriented correctly. Unfortunately there are no marks for pin 1 of both DIP sockets on the silkscreen. They should be oriented with the notches near the buttons, like seen on my photo. The PLCC socket should match the outline on the silkscreen.

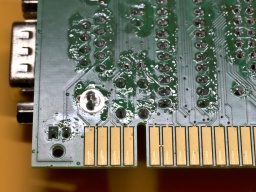

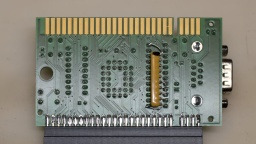

The edge connector is usually meant to be soldered upright, not to the edge of the PCB, so you first need to bend the pins to the inside. If done correctly, the edge connector should sit centered, and all pins should touch the pads of the PCB. Also make sure to solder the connector to the correct side of the PCB, which is the one with the short pads. The connector on the other side is meant for further expansions, like a joystick interface, but you can even stack multiple Dandanators together.

If you intend to use the 3D printed case, leave a gap of about 2 mm between the PCB edge and the connector.

Some of the pads are close to the edge connector on the back. It's easy to spill some drops of solder on the pads while soldering. A bit of Kapton tape is a good way to protect them.

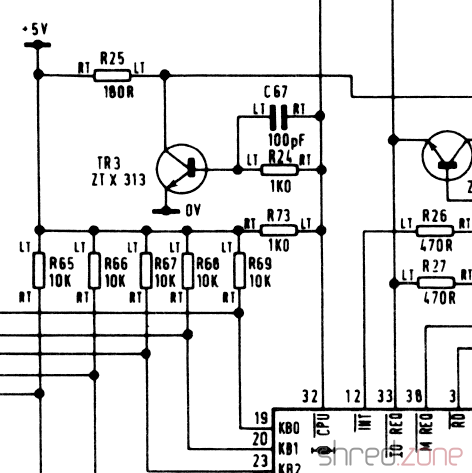

A problem with the ATF22V10C is that it does not provide internal pull-ups at the inputs. This means that if no joystick is connected, the inputs are floating, which could lead to problems. On my system, if no joystick was connected, the first game on the list was always started immediately. A possible solution is to solder a bussed resistor array to the bottom side. The resistors are connected to pin 8, 9, 10, 11, and 13 of the ATF22V10C. The common bus is connected to pin 24. Take care not to connect or short circuit adjacent pins.

This problem should not arise with the ATF22V10B, but at the time of writing, this variant was either out of stock or ridiculously expensive.

While this issue likely won't occur with older GALs, the manufacturers still recommend not to let input pins open. In my oppinion, the pull-up resistors should have been a part of the Dandanator design.

In a final step, clean the board and inspect it for solder bridges and other errors. A short circuit can damage the power converter inside the ZX Spectrum, which is a bit difficult to repair.

The "Joystick" header is for enabling the joystick port, and should be bridged unless you plan to use another joystick interface. The "Serial Pins" header seems to be there for in-circuit programming, and should not be bridged. (It won't cause any damage if you accidentally bridge it, but it will be like permanently pushing the joystick to the right.)

When the assembly is done, the next step is to program the chips. They all are programmed differently.

Flashing the Chips

- GAL: The fusemap can be downloaded here. If you use an ATF22V10 and the XGecu programmer, make sure to select the

(UES)variant as chip type. - PIC: An initial firmware can be downloaded here. I have tried to flash it with the minipro software, but could not get a working PIC from it. Eventually I used the original software from XGecu, which worked fine.

- Flash ROM: The Flash ROM contains the games and also pokes. The image file is generated by a ROM assembler tool.

The ROM assembler is written in Java, so it runs on any modern OS. If you know about Java, you can easily build the latest version from source yourself. You can also download a jar file from the Dandanator download page and run it with the command java -jar dandanator-mini-*.jar.

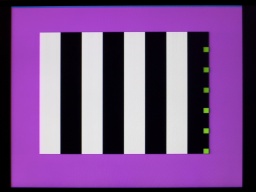

The ROM assembler GUI is quite self-explanatory. You can just drag&drop TAP, SNA, Z80, and POK files of your favorite games into it until the Flash memory is full. In the settings, you can change the font, language, and also use an individual background picture.

A lot of games can be found at World of Spectrum. An extensive collection of POK files can be found here.

When you're done collecting your own favorite games, create a ROM image and write it to the Flash ROM.

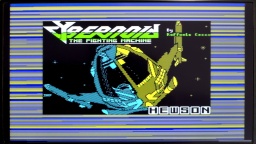

Let's Play

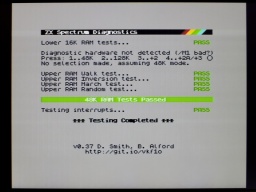

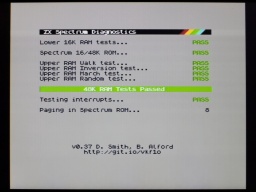

The Dandanator is connected to the expansion port of the ZX Spectrum. Remember to disconnect it from power first.

Now power on your Speccy, and press the right button on the Dandanator to reach the main menu.

You can pick a game, either by using the joystick or pressing the corresponding key, then change the pokes to be applied, and then start the game.

If it's the first time you run the Dandanator, it's recommended to power off the Speccy, then keep both buttons depressed and power on again. The Dandanator will then flash the latest firmware version to the PIC.

The right button will always bring you back to the main menu. No need to reset the machine anymore.